Grasping the Needlework Digitizing Process: Your Ultimate Overview

Needlework digitizing is a careful craft that requires accuracy and knowledge to convert elaborate styles into digital styles for device needlework. As artisans get started on this trip to grasp the needlework digitizing process, a detailed understanding of the basics sets the structure for excellence.

Recognizing Needlework Digitizing Basics

Needlework digitizing fundamentals create the foundation whereupon complex designs are equated into machine-readable layouts for exact sewing. This preliminary action in the embroidery digitizing process is vital for ensuring that the final embroidered product is a devoted depiction of the initial style. Recognizing needlework digitizing essentials includes understanding crucial ideas such as stitch kinds, sew direction, density, padding, and pull settlement.

Stitch kinds play an essential duty in determining the visual and textural end result of the embroidered design. By picking the proper stitch type, whether it be satin, fill, or running stitch, digitizers can attain the wanted effect and improve the general high quality of the embroidery. Furthermore, stitch instructions influences the flow and measurement of the style, while density determines the spacing and insurance coverage of the stitches.

Additionally, padding stitching offers security to the layout by safeguarding the fabric and preventing distortion throughout the needlework process. Draw settlement is one more important factor to consider to neutralize the natural propensity of textile to agreement when stitched. Grasping these needlework digitizing basics is essential for producing professional-quality stitched items.

Selecting the Right Digitizing Software

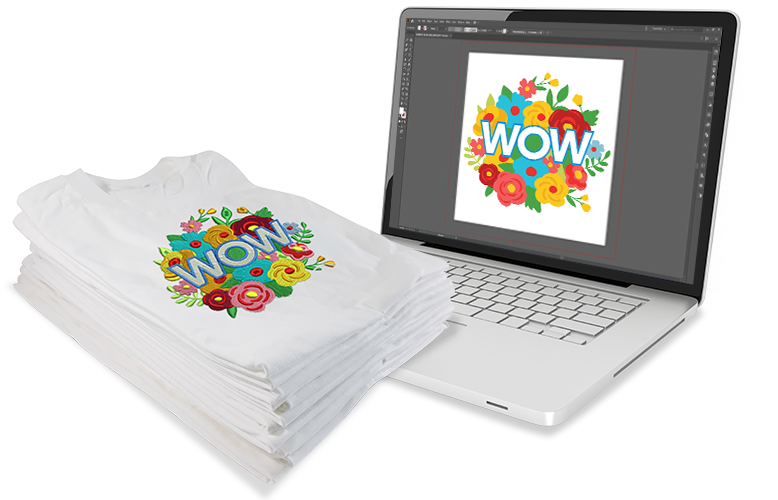

Selecting the ideal digitizing software application is a critical choice that considerably influences the efficiency and top quality of the embroidery digitizing procedure. Digitizing for Embroidery. When choosing the best digitizing software application, it is important to take into consideration elements such as the complexity of designs you plan to produce, the user-friendliness of the software application, the degree of consumer support supplied, and the compatibility with your embroidery device

There are numerous digitizing software application alternatives readily available in the marketplace, ranging from fundamental programs for novices to advanced software application for professional digitizers. Some popular choices include Wilcom EmbroideryStudio, Hatch Embroidery Software, and PulseID. These software provide a broad range of devices and features to aid you develop elaborate styles effortlessly.

Prior to deciding, it is a good idea to explore the different software options through totally free tests or demonstrations to determine which one finest fits your demands. Additionally, reading evaluations and looking for recommendations from experienced digitizers can supply useful insights into the strengths and weak points of each software (Digitizing for Embroidery). By carefully reviewing your needs and contrasting the features of different digitizing software, you can make an informed choice that enhances your embroidery digitizing operations

Digitizing Tools and Methods

Optimizing Layout Settings for Needlework

Mastering the complexities of style setups is fundamental in achieving ideal results in the needlework digitizing procedure, structure upon the foundation laid by recognizing digitizing devices and strategies. When maximizing style settings for needlework, it is crucial to take into consideration elements such as stitch kind, thickness, padding, pull settlement, and enrollment. Registration setups align different elements of the style properly, preserving overall layout honesty.

Troubleshooting Common Digitizing Issues

When encountering typical digitizing concerns throughout the needlework procedure, it is important to understand the origin and execute reliable solutions promptly. One common trouble is stitch thickness problems, where stitches might be too dense, causing the textile to tighten, or as well sparse, leading to voids in the style. Changing the stitch thickness setups in the digitizing software right here application can help solve this concern.

One more frequent obstacle is string breaks during the needlework procedure. This can happen because of different reasons such as incorrect stress settings, plain needles, or making use of low-grade string. Guaranteeing correct upkeep of the embroidery equipment, consisting of routine needle changes and stress changes, can lessen the event of thread breaks.

Furthermore, layout enrollment errors can result in misaligned components within the needlework layout. Examining the layout alignment in the digitizing software application and making essential changes prior to sewing can help in preventing this issue. By attending to these common digitizing problems immediately and efficiently, you can ensure a smoother embroidery procedure and premium completed products.

Final Thought

Finally, grasping the embroidery digitizing procedure calls for a solid understanding of the basics, the Continued right choice of software, and knowledge of devices and strategies. Optimizing style settings and troubleshooting usual digitizing concerns are vital action in making sure top notch needlework results. By following these steps diligently, one can accomplish precision and efficiency in the digitizing process.